|

(c) 2012 - 2017 * updated MAR 2020 |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

|

|

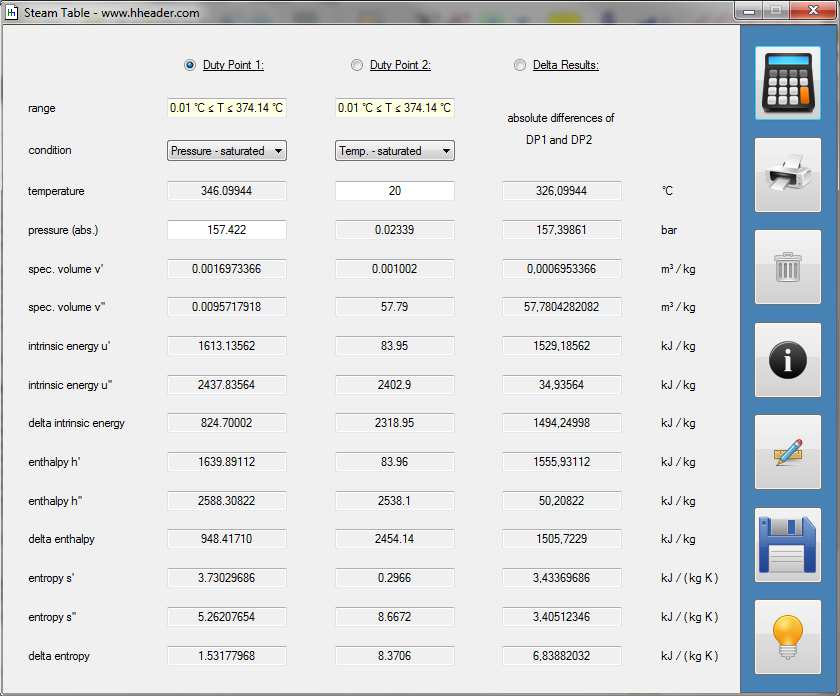

Category 7 - Mixed: Steam TableThe program and the provided calculations refer to water vapor, only. Generally steam can occur either if liquid evaporates or solid sublimates. During sublimation the transition from the solid the gaseous phase takes place directly without the appearance of the liquid phase. The evaporation behavior of water depends mainly on two parameters which are temperature and pressure. While there are no further outer influences temperature and pressure are directly in coherence to each other. Beside this the following variables are relevant: the specific volume, the intrinsic energy, the enthalpy and the entropy. Internal tables are provided for saturated, sublimated, superheated and supercooled steam. |

||||||||||||||||

|

|

||||||||||||||||

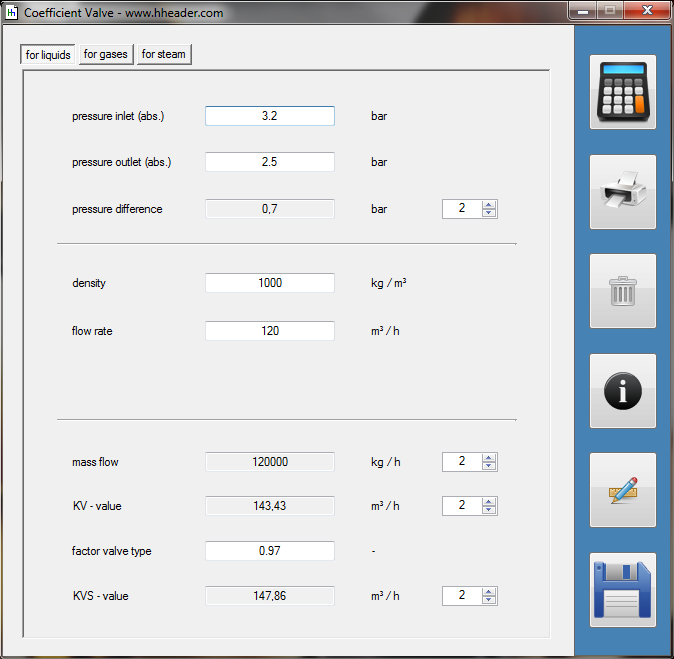

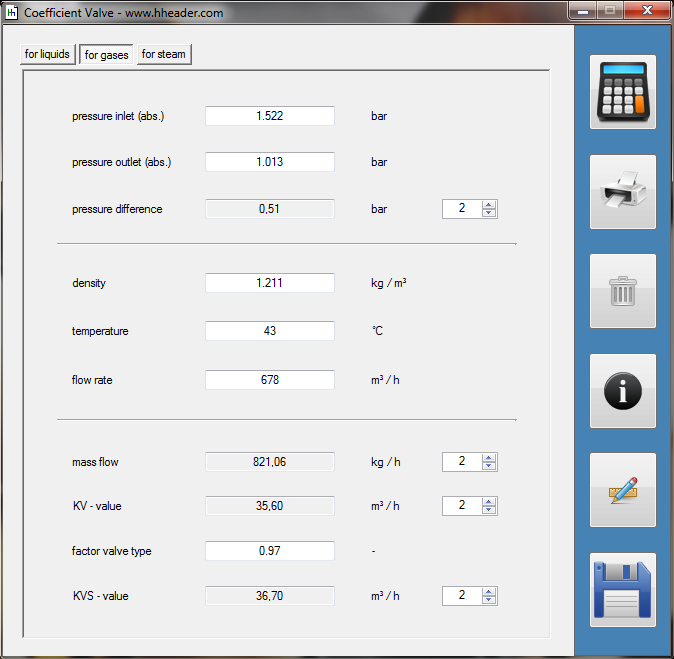

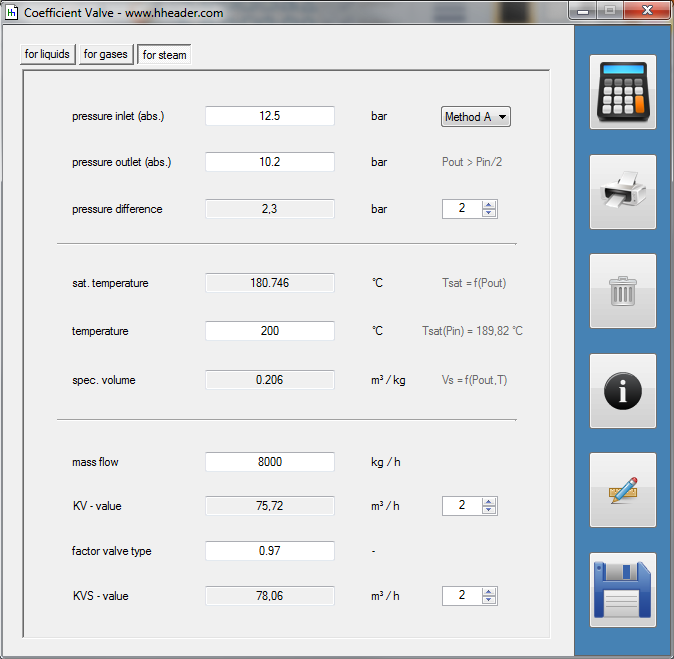

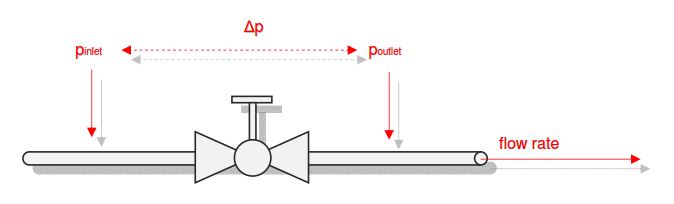

Category 7 - Mixed: Valve CoefficientThe valve coefficient is a measure for the flow rate that can pass through a valve with respect to the pressure drop under the given circumstances. The valve coefficient that is also known as KV-value is relevant for an adequate choice of a proper valve type. Depending on the medium there are different equations with different variables to consider. Calculations for liquids, gases and steam are provided. The coefficient for the valve (KV-value) gives at least the flow rate that will cause a pressure drop of approximately one bar while passing through the valve under the given circumstances. The KV-value and the KVS-value are in coherence with each other. |

||||||||||||||||

|

|

||||||||||||||||

Category 7 - Mixed: Open Area ValveControl valves react on different process circumstances. In order to adjust the target value they open or close step by step according to the adjusted controller parameters. In case of continuous and stabile process conditions the valve operates in a predictable range as percentage value for its opening grade. This depends on the valve type. The program provides calculations for three different valve types. These are butterfly valve, ball valve and gate valve for a circular cross section pipe. The effective control point is the grade of opening as a percentage value of the specific measures for the valve types. The projected open area can be an important measure for evaluation purposes. It results out of the pipe diameter and the effective control point for the valve under consideration of the used valve type with its specific opening measure. |

||||||||||||||||

|

|

||||||||||||||||

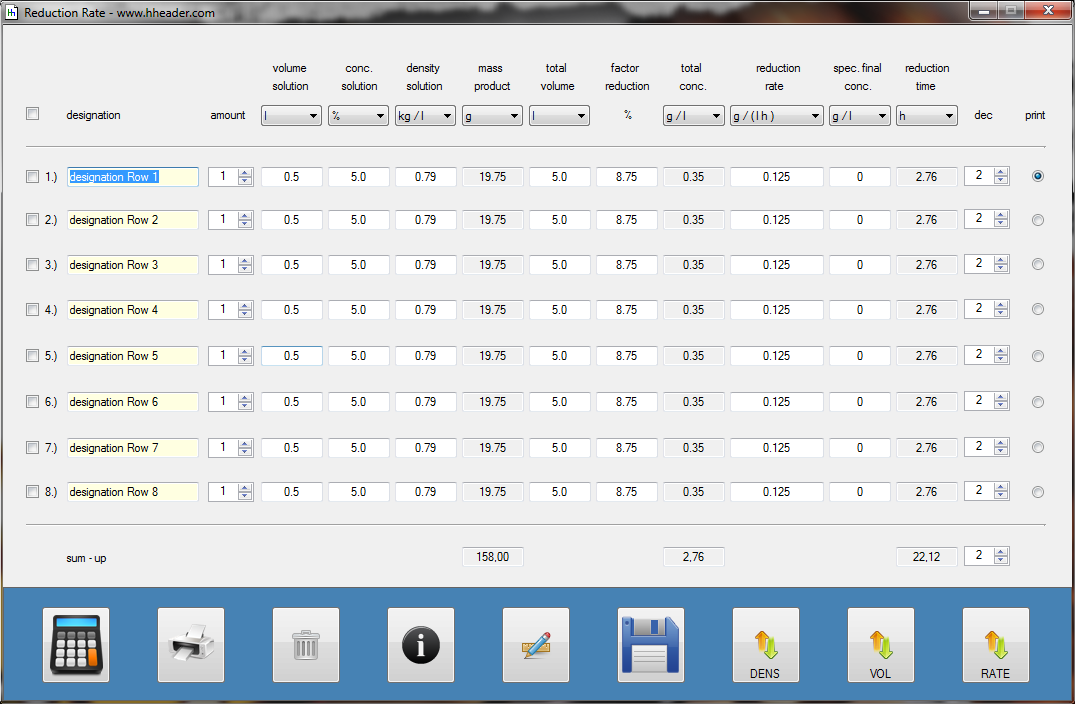

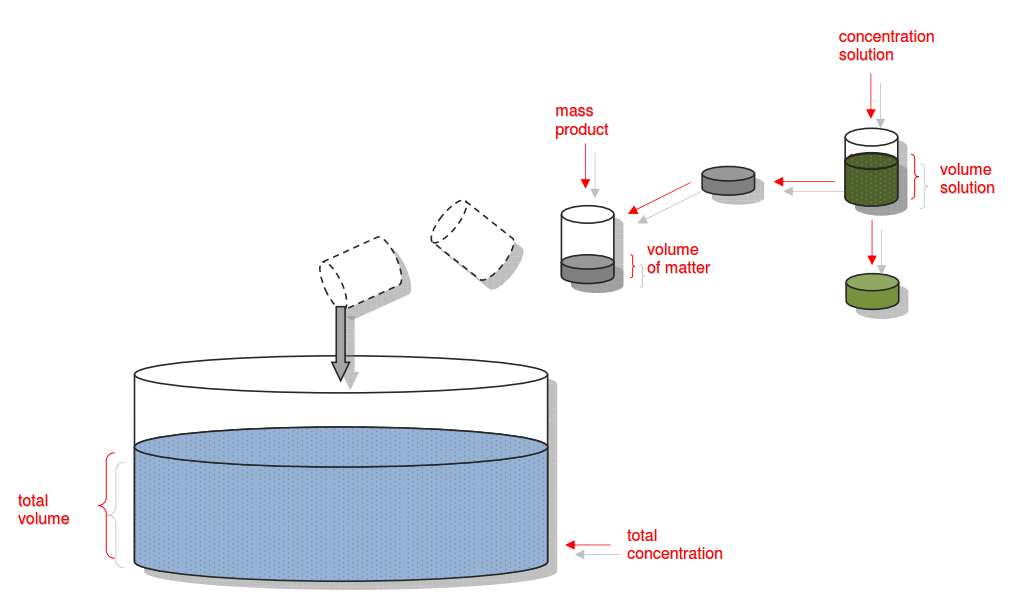

Category 7 - Mixed: Reduction RateReduction processes can be relevant for the treatment in different use cases. They can have a biological, a physical or a chemical inducement. Even a combination of two or three of them is also possible. Although the reduction is in almost every case not linear, a linear approximation can be used in many cases for a long term evaluation. To cover most of the possible cases, the following situation is simulated by the program. A certain volume of a solution with a certain density and a certain concentration of matter appears x times, where x can be a natural number from 0 to 99. The total mass of matter inside the solution that results according to the given values is distributed or further diluted in a total volume. |

||||||||||||||||

|

|

||||||||||||||||

Category 7 - Mixed: GeometryFrom time to time it is required to calculate the area or the volume of different geometric shapes. The program provides eleven different calculations regarding each of these subjects. The following shapes are provided for the area calculations: rectangle, rhomboid, trapeze, triangle, regular polygon, circle, circle part, circular section, circular ring, circular ring section, ellipse. The following shapes are provided for the volume calculations: prism square, cylinder, hollow cylinder, pyramid, cone, truncated pyramid, frustum, ball, spherical section, spherical layer, spherical sector. |

||||||||||||||||

|

|

||||||||||||||||

|

||||||||||||||||

|